Racking

Flowthrough Racking

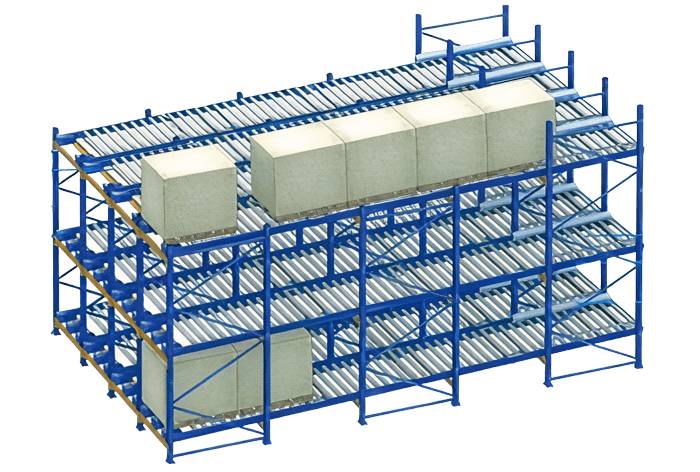

Live Storage | Gravity Flow Racking

Flowthrough Racking

Gravity Flow

It provides excellent stock rotation as it is First In First Out ‘FIFO’.

‘Live Storage’ or ‘Flow Through’ racking features lanes of conveyor rollers on a slight incline, which allows the pallets to roll forward by gravity at a controlled speed. Flow through or live storage racking is essentially the same as Push Back except that it is loaded from the back and unloaded from the front. Gravity Flow is not limited to 6 deep as with the Push Back system. You can have as many pallets deep as you like.

Supplying Systems Since 1986

Let us get involved in the initial design stages of your new project, you never know what problems we may be able to solve for you.

Novalok’s engineering team will assist you with the documentation process to enable your organisation’s racking project to be ‘Certified’ as compliant with the relevant standards. Furthermore Novalok assures you that our products will meet all required installation and manufacturing standards, subject to proper use and operation within maximum load ratings.