Case Study – Farmers

Novalok has worked with Farmers (Farmers Trading Company) over the last couple of years carrying out 8 major store fitouts plus numerous smaller refurbishments. Farmers was requiring increased storage capacity on less footprint area and Novalok was able to provide the perfect solution with custom manufactured mobile storage units with some standard static shelving for areas around the walls of the storage facility.

Custom manufacture & onsite installation of mobile storage system

Novalok”s team of designers, engineering/fabrication experts and installation team worked with Farmers to ensure the custom manufacture and onsite assembly and installation process ran smoothly.

Extra shifts were successfully managed at the Novalok manufacturing facility to provide a product supply line as and when required on site. Installation at the Farmers’ sites had to be carefully managed to cater for the logistics of other trades and personnel being in the vicinity.

The Result: a customised mobile storage system that caters specifically for the requirements of each Farmers store

The result for Farmers is:

an exceptional “turn-key” mechanically assisted mobile compacting system that is very robust, easy to operate and cost effective.

a special customised design that provides fantastic flexibility in efficient storage of a huge range of products from toys to clothing.

Features of the system include:

mounted on heavy duty steel chassis carriageways and roller system.

diagonally braced internally for maximum latitudinal rigidity and minimal structure flex to help prevent wear on moving parts.

easy “clip-in”, “clip-out” modular horizontal beams to allow easy adjustment of shelf levels to maximize storage efficiencies of many and varied product sizes and weights.

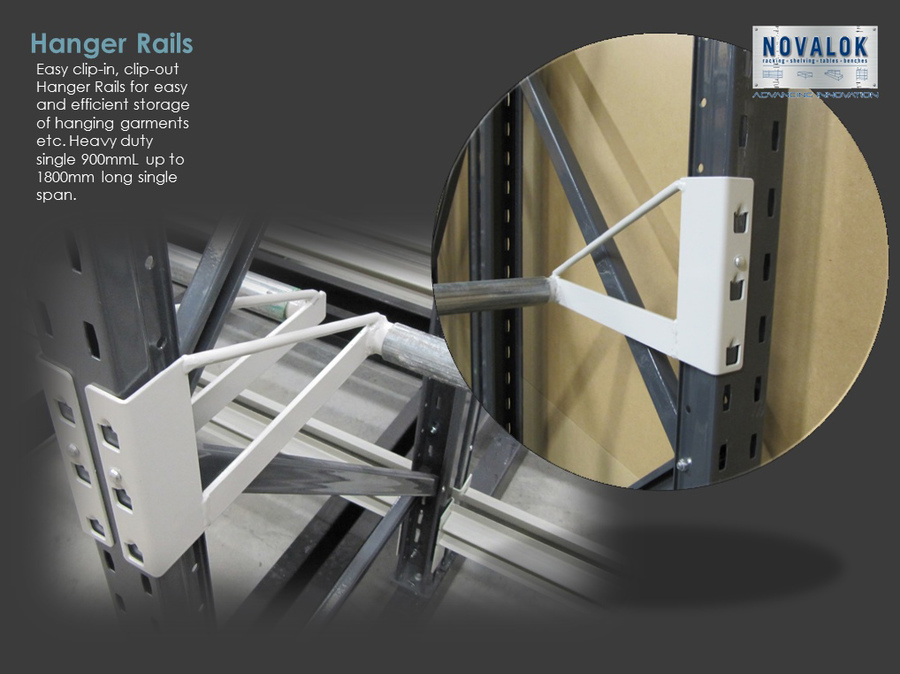

incorporated heavy duty modular “clip-in” hanging rails for storage of garments.

ergonomic handle with folding hand wrench for easy and safe operation

all moving parts covered to prevent catching or damage to the product being storeddesigned for minimal rolling friction to prevent operator fatigue or injury

attractive “two-toned” epoxy powder-coated components to enhance the aesthetics

Novalok has successfully worked with Farmers management to ensure all structures are fire compliant. This includes providing a modular wire mesh deck shelf system with under support.

All shelving supplied as fully NZ building code compliant including (but not limited to);

AS4084-1993 – Steel Storage Racking (Australia)

AS/NZS1170 – Structural Design Action

NZ3404-2009 – Steel Structures

FEM – European Fed of Engineering

BRANZ – Design of Standard/High Level Racking Systems

HERA – Design of Shelving/Pallet Racking

SEMA – Specialty Equip. Association

Full after sales support & maintenance

Full after sales support is available from Novalok’s design team to the Farmers store operators on best operational use of the systems. A full maintenance programme was set in place to ensure minimal damage/wear ongoing with operation of the systems. Novalok is committed to excellent after sales service and support. for all our customers.

More mobile storage unit product facts

Mobile Storage Units offer compact storage and reduce the floor area required for conventional storage systems by up to 50%. That’s twice the storage in half the area. Units available as Free Track, Mechanically Assisted, or Manually operated. Manually operated units glide with fingertip pressure whereas mechanically assisted units operate by crank handle or wheel. Mobile units glide easily along tracks and are configured to suit your space and storage requirements. Units can be relocated if required, and are available in a range of standard colours

Leave A Comment

You must be logged in to post a comment.