Novalok presents Modula Lift Carousel V.7

Your fully automated storage solution

Ready for a revolutionary range of storage automation?

Modula Lift, the next generation of Vertical Lift Carousel, is the ideal solution for any warehouse.

Modula Lift, the next generation of Vertical Lift Carousel, is the ideal solution for any warehouse.

The Modula Lift Carousel is a fully automated vertical storage system that provides better storage and retrieval of any products or goods in a variety of different work environments.

Using the Modula Lift Carousel will increase the floor space available within your facility or warehouse by utilising the ceiling height available.

Modula Lift V.7 is an evolution of the previous model and thanks to the high storage capacity (60,000 kg free load capacity and over 8402 m. into 142m. of footprint only), is designed to store and retrieve any parts, components, goods and finished products.

Novalok is proud to supply the Modula Lift Carousel shelving solution to the New Zealand market. With is advanced features such as the high technology console and wide range of sizing, the Modula Lift Carousel is one of the leading vertical storage systems available.

High performing automated storage that is environmentally friendly

Concerns for the environment and the need to save energy saving has driven the design of the new Modula Lift to ensure significant energy savings whilst guaranteeing a lower environmental impact.

Concerns for the environment and the need to save energy saving has driven the design of the new Modula Lift to ensure significant energy savings whilst guaranteeing a lower environmental impact.

Compared with the previous Modula model, the lower energy consumption is achieved by smaller size motors that have a higher efficiency rate. The 3 kW vertical axis motor, also used for the 750 kg model, provides a significant energy savings.

The ModulaGreen ® optional device provides even further savings by recovering the energy produced as the lift is lowering the tray to the picking bay, energy that would be otherwise dissipated and lost. This option gives a return of the investment in just few months time.

Optimise your warehouse space

The new Modula Lift Carousel vertical storage system excels itself: over 8402 m. of products can be stored in an actual occupied space of about 14m2 . The Modula Lift Carousel goes up to 14 meters in height, optimises the storage volumes and gives a very high throughout.

The Modula Lift Carousel can store the trays with 25 mm pitch distance and is designed for a vertical modularity of 200 mm step, the product height optimisation in the Modula Lift Carousel occurs through photo cells maximizing the total number of trays inside the unit. Sidewall trays extension, adjustable partitions and dividers are available to slot the inner surface of the trays and ensure the highest operating flexibility.

If you have a wide industrial unit then your space can be further optimised installing multiple Modula Lift Carousel machines side by side. The modular structure and the new generation of software enable the machines to reciprocally communicate and allow a single operator to manage several units in the same environment, optimising operations and working waste time. Storing and retrieval operations of each unit can be synchronized to increase efficiency and optimise operator working time.

A fully automated storage solution that is ergonomic and efficient

The Modula Lift Carousel external bay provides maximum performance thanks to the ergonomics of the working station and increases the safety level for your operators. Businesses that use external tools for handling the product, such as robots and manipulator arms are also facilitated. The internal picking bay, with a reduced carbon footprint, provides space savings if the work area is particularly narrow.

The internal or external dual tray delivery system provides an outstanding throughput and eliminates waiting times with the Continuous Picking feature: while the operator picks the product, the automation makes the next tray available on the second exit. Operators are walked through the storage and retrieval operations via a dedicated and user friendly computer interface and an optional Pick to Light bar.

An advanced technology console to manage your workload

Modula Lift Carousel has a colour touch screen console, designed for the industrial environment, that enables the operator to control the VLM. The graphic interface is completely new, developed with user friendly icons and is very intuitive for the operators so they don’t need any special training for daily use.

Modula Lift Carousel has a colour touch screen console, designed for the industrial environment, that enables the operator to control the VLM. The graphic interface is completely new, developed with user friendly icons and is very intuitive for the operators so they don’t need any special training for daily use.

To ensure the safety of the products stored in the warehouse, the operators have access to the VLM through passwords that differentiate the accesses to the VLM, depending on the tasks and on the roles.

A wizard menu supports the operator in managing the VLM reducing inefficiency and wasting time. The console incorporates the automatic functions for managing scheduled maintenance interventions.

The system is designed to check, in real time, quantities stored, for a complete product traceability. Any storage or retrieval operation is recorded in a log file that can be downloaded any time.

Modula WMS

For the integrated management and control of automated storage units, System Logistics has developed MODULAR WMS an extremely advanced supervision software that can interact with any ERP.

Modula WMS manages two levels of subcodes, allowing the lot management with an accurate traceability of the goods in the VLM, through parameters such as production date, lot number, expiring date, and so on.

The Modula WMS can manage the following:

• Goods reception

• Production lot management

• Pinpointing the best handling strategies

• Order preparation

• Stock check and statistical surveys

• Integration with all management “host” systems

• Packing lists

• Radio-frequency

• Management of the areas for reception, shipment, quality control, etc.

• Goods flow management and control

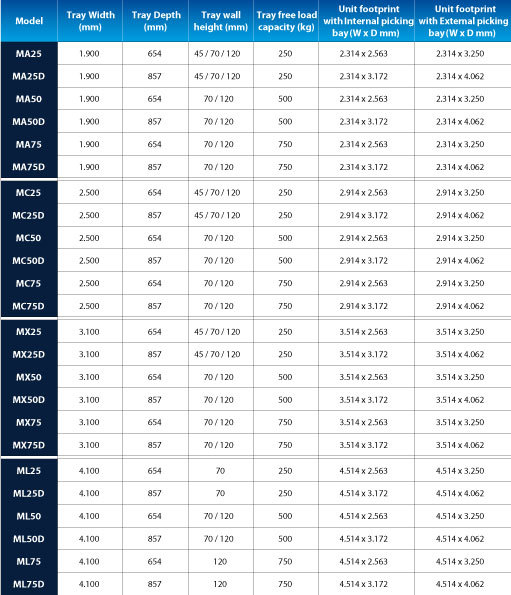

A wide range of sizes to suit your products

Leave A Comment

You must be logged in to post a comment.